Based on the ubiquitous 308 Winchester, the 243 Winchester has developed a strong following among rifleman. The 243 Winchester’s 6mm (.243″) bullet offers reduced recoil and the ability to use lighter, faster bullets for varmints and small game, while heavier, 100 grain loads can be used to harvest deer. Beyond hunting use, the 243 Winchester has adopted a following in competitive rifle circuits, where the fast, 6mm bullet offers low recoil, flat trajectory and match winning performance.

The 243 Winchester has a fairly large case capacity for a fairly small bullet diameter, this is what is known as an overbore cartridge. Overbore cartridges tend to be characterized by high muzzle velocities, use of slower burning powders, longer barrels and relatively short barrel life due to throat erosion. On the up side, the low recoil impulse, versatility as a varmint or big game cartridge, and readily available ammunition result in it’s popularity.

In this post, a continuation of Rifleshooter.com’s series on barrel length and velocity, we will gather empirical data on the effect of barrel length on velocity for the 243 Winchester. Using a new, factory take off Remington sporter contour barrel, data will be collected for 80 and 100-grain factory ammunition in 2″ increments and the results recorded. Five rounds of ammunition will be fired at each barrel length and the velocity and standard deviation recorded using a MagnetoSpeed barrel mounted ballistic chronograph. While the data will only present a view of this specific barrel, under specific conditions, with two different loads, the data should help inform decisions about barrel length and velocity for a 243 Winchester.

Before we get to the good stuff, please take the time to review the disclaimer below:

The contents of Rifleshooter.com are produced for informational purposes only and should be performed by competent gunsmiths only. Rifleshooter.com and its authors, do not assume any responsibility, directly or indirectly for the safety of the readers attempting to follow any instructions or perform any of the tasks shown, or the use or misuse of any information contained herein, on this website.

Any modifications made to a firearm should be made by a licensed gunsmith. Failure to do so may void warranties and result in an unsafe firearm and may cause injury or death.

Modifications to a firearm may result in personal injury or death, cause the firearm to not function properly, or malfunction, and cause the firearm to become unsafe.

The test process is fairly straight forward. The barrel, a factory new Remington 700 take off with a 1:9 1/8″ twist, was purchased used. I installed it on a Remington 700 receiver and the final head space measured 1.633″, which is .003″ above SAAMI minimum head space specification. The test rifle is shown below:

The rifle is equipped with the following parts from Brownells:

- Remington 700 short-action receiver

- MDT HS3 chassis

- MAGPUL PRS stock

- MDT AICS style magazine

- Harris BR bipod

Yes, the receiver is red, Cerakote USMC Red to be exact. It was actually borrowed from another project, a Remington 700 chambered in 7.62x39mm Russian.

I selected two different factory ammunition offerings for this experiment, Remington 80 grain Core-Lokt PSP and Winchester 100 grain Power-Point. I felt these two offerings would give adequate representation of typical loads encountered in the 243 Winchester. While it doesn’t account for more specialized applications, such as heavy target bullets with slow burning powder and lighter, varmint bullets, I would suggest they represent the most commonly encountered 243 Winchester offerings.

The barrel started at 24″ in length. Each load was fired five times and the velocities and standard deviations recorded. The rifle was then cleared, and 2″ was cut off the barrel using a cold saw. The experiment was repeated until the barrel was 16″ long. This provides data for barrels 24, 22, 20, 18, and 16″ long.

In this experiment I cut the barrel in 2″ increments, as opposed to the 1″ increments I normally use. This was decision was made based on the very thin diameter of the barrel. Typically, I cut straight or heavy contour barrels. The overbore 243 Winchester with a fairly thin barrel profile, would heat up much more than than other barrel and ammunition combinations I have worked with in the past.

A quick note on range conditions. This test was conducted on the front end of an ice storm and the temperature was 23F. This is notable when comparing velocity figures. While modern powder tends to be less temperature sensitive than older powders, the low temperature will undoubtedly yield slightly lower velocities than those expected at higher temperatures.

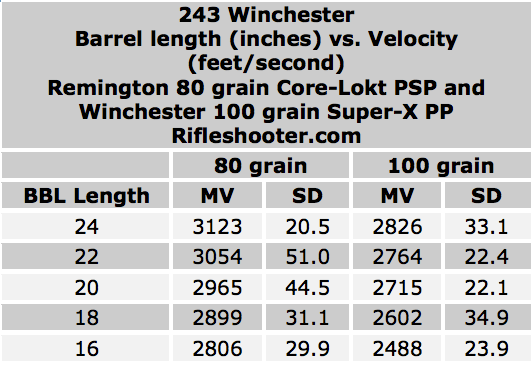

Results are shown below:

Results by cartridge:

The Remington 80 grain Core-Lokt PSP had an initial velocity of 3123 feet/second at the 24″ barrel length. At 16″, velocity was 2806 feet/second, a reduction of 317 feet/second. Average velocity reduction was 39.6 feet/second per inch of barrel length.

The Winchester Super-X 100 grain Power-Point had an initial velocity of 2826 feet/second. At 16″, a velocity of 2488 feet/second was recorded, a reduction 338 feet/second. Average velocity reduction was 42.3 feet/second per inch of barrel length.

What are possible sources of error?

Sample size. Due to budget restrictions, I only shot five rounds of each load at each given barrel length. As sample size increases, so does the validity of the results. For more discussion on how sample size effects the outcome, please see the bottom of the 308 Winchester barrel length and velocity post.

This test controlled for the barrel, which, in my opinion, is better than comparing velocities between different rifles with different barrel lengths.

Did you shoot any groups?

No, I did not. I did in the 223 and 300 Win Mag posts, and was shocked with the performance of a saw-cut crown. Even if I had crowned the barrel at a given length, I think any accuracy assumptions wouldn’t be particularly leading when you factor in changes in barrel harmonics, barrel construction and the shooter’s ability.

Why didn’t you crown the barrel each time you cut it?

Time. My lathe is a two hour round trip to the range. Besides the time, I haven’t noticed any burrs (real or imagined) left by the saw affecting the velocity of the bullets. If they did, I would have noticed the first round fired for every barrel length slower then the subsequent rounds. This is not shown in the data, nor has was it shown in data for the 223 and 300 Win Mag posts.

What do you think of the MDT HS3 chassis?

I love it. It is a solid value for the money. For more information about the MDT HS3, visit MDT’s website here.

What did you think of the MDT AICS style magazine?

It works great with the 243 Winchester. I haven’t encountered any magazine related problems with it in various different firearms. I’ve run 6.5 Creedmoor, 243 Winchester, 7.62x39mm Russian and 308 Winchester in it and have had great results.

How would you respond to criticism like this?

I found this on Facebook, in regards to the 6.5 Creedmoor barrel length experiment,“I too love the 142 SMK. From a statistical standpoint, the article is bunk. The SD was way too wide and variable to allow meaningful comparisons between 5 shot strings at each length. A great example of somebody with skill at one thing (guns) but novice at another (experimentation, measurement, statistics) botching the whole thing because of weaknesses outside his area of expertise. He should have consulted somebody. And he would have had more measurement precision firing 10 shot strings and cutting off two inches at a time”

I am unsure where the novice comment comes from. I would suggest rereading what I wrote as it was presented. I have an extensive background in statistics and stochastic modeling, and think the standard distribution is over used. Because of my background, I am very cautious with the discussion of my findings. Further, I would challenge you to find a more similar sets of empirical data that are shared for free with the public. As mentioned above, I agree with sample size. However, take a look at this from my 308 Winchester post, and how the results change with sample size:

Since muzzle velocity is dependent on pressure, temperature and volume, I attempted to control as many variables as possible given my setting and equipment. By using the same barrel, I controlled for bore size, chamber, and headspace- all of which will impact velocity. Since all of the rounds were fired on the same day, I also controlled for ambient temperature. I did not control for barrel temperature. The barrel did heat up during firing. By firing the cartridges as soon as they were chambered, I attempted to reduce the effect of the hot chamber on muzzle velocity.

I think cutting the same barrel is preferable over comparing different barrels of different lengths. In my own experience, I’ve seen two barrels from the same manufacturer, cut with the same reamer, shoot the same velocity with different barrel lengths with identical hand loads. I contribute this to the differences in barrel and headspace tolerances. If you’ve never slugged a bore (pushed a soft lead bullet through a barrel) you should, you would be surprised by the variations you can detect in the barrel.

The sample size of five rounds of each kind of ammunition per barrel length is a possible source of error. However, testing indicates it may not be as much as initially thought. I fired 30 rounds of IMI Samson 150 grain FMJ at 28″ and 16.5″ and recorded the results. Comparing the data from the 30 shot strings (28″ 2824 and 16.5″ 2555) to the 5 shot strings (28″ 2823 and 16.5″ 2561) I found a loss of 269 ft/sec (23.4 ft/sec per inch) as the barrel was cut. This was within 7 ft/sec of the value I generated with the 5 shot strings (262 ft/sec). Velocity loss per inch of barrel was .6 ft/sec away (22.8 ft/sec) from the value calculated with 5 shot strings.

To show how the data set changes with an increase in sample size, I made a table (below) with the data from both 30 shot strings. The “shot” column represents the shot number in the respective string. “28” barrel ft/sec” and “16.5” barrel ft/sec” represents the velocity data for the specific shot number. “AVG 28″ ft/sec” and “AVG 16.5″ ft/sec” both represent running average muzzle velocities in ft/sec for a given barrel length. “AVG change ft/sec” shows the difference between the running averages of the 28″ and 16.5″ barrels. “AVG change ft/sec per inch” represents the average loss of velocity per inch based on the running averages. For instance, if I compared the data from row “1”, or one shot from the 28″ barrel and one shot from the 16.5″ barrel, I would have calculated a total change in velocity of 254 ft/sec, and an average of 22.1 ft/sec per inch. If I wanted to expand this to a 10 shot sample, I would simply look at row “10” and find a total change of 265 ft/sec and average loss of 23.0 ft/sec per inch of barrel. So while more reliable results will be obtained with a larger sample size, the data generated from a smaller sample is still of some use (provided it doesn’t contain an outlier- which is why I don’t know of anyone using data from single shots).

| 308 Winchester/ 7.62x51mm NATO Comparison of velocity dataRifleshooter.com | ||||||

| Shot | 28″ barrel ft/sec | AVG 28″ barrel ft/sec | 16.5″ barrel ft/sec | AVG 16.5″ barrel ft/sec | AVG change ft/sec | AVG change ft/sec per inch |

| 1 | 2835 | 2835 | 2581 | 2581 | 254 | 22.1 |

| 2 | 2814 | 2825 | 2533 | 2557 | 268 | 23.3 |

| 3 | 2821 | 2823 | 2541 | 2552 | 272 | 23.6 |

| 4 | 2823 | 2823 | 2551 | 2552 | 272 | 23.6 |

| 5 | 2824 | 2823 | 2601 | 2561 | 262 | 22.8 |

| 6 | 2834 | 2825 | 2572 | 2563 | 262 | 22.8 |

| 7 | 2811 | 2823 | 2587 | 2570 | 252 | 21.9 |

| 8 | 2816 | 2822 | 2546 | 2564 | 258 | 22.5 |

| 9 | 2821 | 2822 | 2545 | 2562 | 260 | 22.6 |

| 10 | 2827 | 2823 | 2520 | 2558 | 265 | 23.0 |

| 11 | 2835 | 2824 | 2584 | 2560 | 264 | 22.9 |

| 12 | 2820 | 2823 | 2592 | 2563 | 261 | 22.7 |

| 13 | 2825 | 2824 | 2554 | 2562 | 261 | 22.7 |

| 14 | 2820 | 2823 | 2551 | 2561 | 262 | 22.8 |

| 15 | 2842 | 2825 | 2585 | 2563 | 262 | 22.8 |

| 16 | 2833 | 2825 | 2573 | 2564 | 262 | 22.7 |

| 17 | 2825 | 2825 | 2540 | 2562 | 263 | 22.9 |

| 18 | 2813 | 2824 | 2492 | 2558 | 266 | 23.1 |

| 19 | 2791 | 2823 | 2550 | 2558 | 265 | 23.0 |

| 20 | 2797 | 2821 | 2546 | 2557 | 264 | 23.0 |

| 21 | 2836 | 2822 | 2567 | 2558 | 264 | 23.0 |

| 22 | 2850 | 2823 | 2541 | 2557 | 266 | 23.2 |

| 23 | 2826 | 2823 | 2559 | 2557 | 266 | 23.2 |

| 24 | 2842 | 2824 | 2478 | 2554 | 271 | 23.5 |

| 25 | 2838 | 2825 | 2537 | 2553 | 272 | 23.6 |

| 26 | 2831 | 2825 | 2569 | 2554 | 271 | 23.6 |

| 27 | 2842 | 2826 | 2601 | 2555 | 270 | 23.5 |

| 28 | 2833 | 2826 | 2534 | 2555 | 271 | 23.6 |

| 29 | 2796 | 2825 | 2578 | 2555 | 269 | 23.4 |

| 30 | 2810 | 2824 | 2536 | 2555 | 270 | 23.4 |

If you like this post, subscribe to Rifleshooter.com on the top right side of the page. It is easy and free!

You must be logged in to post a comment.