I often utilize traditional methods to develop hand loads for my rifles. Normally, I’ll load five rounds of a given charge in .3 grain increments for a given powder (some shooters load 3, or 6, for two three shot groups). Each string of rounds is fired into the same target, while velocity information and group size is recorded to determine which load is best. Sometimes I load ten rounds of each charge and shoot two, five-shot groups. The downside to this method, is it uses a lot of powder and bullets.

The ladder test is another technique popular with long range shooters. To conduct a ladder test, a shooter starts at the published minimum load for a given powder in their manual and load cartridges in .3 grain increments to the maximum. Each cartridge is fired at the same target, typically 200 or 300 yards away, and the impact of each round recorded (serious long range competitors will conduct ladder tests at the ranges up to 1,000 yards). The idea is to look for clusters of rounds impacting in the same area, this would indicate an accuracy window or optimal load range (and would likely be the most accurate loads for a given rifle and bullet combination).

For traditional ladder testing, shooters would start at the published minimum load and work up a ladder with 20 cartridges. I’m not interested in having my 308 perform like a 30-30, so slow and accurate loads don’t appeal to me. Since I already have data on this rifle, I started at my safe maximums and worked down in .3 grain increments for a total of 10 loads for each given cartridge.

I’ll be shooting my ladder tests at 200 yards, since this is the longest distance available at the range closest to my home.

Today I am working with the ubiquitous 175 grain Sierra MatchKing (SMK).

For powders, I’ll be using Varget and IMR 4064. I’ve been using Varget for years and love it. I haven’t done much work with IMR 4064, however, my interest piqued since it is used in the U.S. military’s “Cartridge, Caliber 7.62mm Special Ball, Long Range, MK 316 MOD 0”. The MK 316 MOD 0 cartridge was developed to replace the M118 LR, by providing greater accuracy and less temperature sensitivity. Both cartridges use the 175 grain SMK projectile. The M118 LR uses Reloader 15 powder.

My rifle is a 22″ 308 Winchester with a Shilen barrel and a Remington Action. The rifle was built with the following parts from Brownells:

- Remington 700 short-action

- McMillan A5 stock

- Surgeon bottom metal

- Timney 510 trigger

- Surefire brake

- Shilen #7 select match barrel

- Nightforce 3.5-15x50mm F1 Mil/Mil Scope

- Spuhr scope mount

- Badger Ordnance Embedded Front Rail (EFR)

If you’d like to read about how the rifle was built, please see:

- Building a Custom Remington 700 .308 Tactical Rifle

- How to cut and crown a rifle barrel and install a brake

- Troubleshooting a .308 rifle

The Lapua brass I am using has been fired twice in this rifle. Cases were neck sized, trimmed to length and cleaned in an ultrasonic cleaner. Charges were dispensed using an RCBS Chargemaster.

Ballistic information was recorded with a Magnetospeed V3 barrel mounted ballistic chronograph. All velocity information is presented below.

To say range conditions were less than ideal would be an understatement (unless you lived in the Yukon). Temperature was 31F, sun was at 12 o’clock to the firing line, and there was 12-30″ of snow on the ground depending on where you walked. This is what it looked like:

I don’t know if it is possible to have worse lighting conditions then this (I spent just about 4 years in the desert as a jarhead- so I know bad lighting). It is actually brighter than the picture shows, the camera darkened up quite a bit from the direct sunlight.

All rounds were fired from the bench, with a bipod and rear bag. I couldn’t shoot prone, since the snow was too deep.

WARNING: The loads shown are for informational purposes only. They are only safe in the rifle shown and may not be safe in yours. Consult appropriate load manuals prior to developing your own handloads. Rifleshooter.com and its authors, do not assume any responsibility, directly or indirectly for the safety of the readers attempting to follow any instructions or perform any of the tasks shown, or the use or misuse of any information contained herein, on this website.

My Varget ladder. Because of the light I had to walk downrange three times to locate shots I couldn’t pick up with my Mark 4 Spotter or rifle scope. That’s a lot of snow to walk through without snow shoes. You’ll notice the 44.2, 44.5 and 44.8 grain loads impacted within .420″ (.229 MOA) of one and other.

Using the traditional methods and firing 5 shot groups, I determined that 44.5 (#6 in picture below) and 44.8(#7 in picture below) grain loads deserved a second look. The results of the ladder test matched my previous load development findings.

On to IMR 4064.

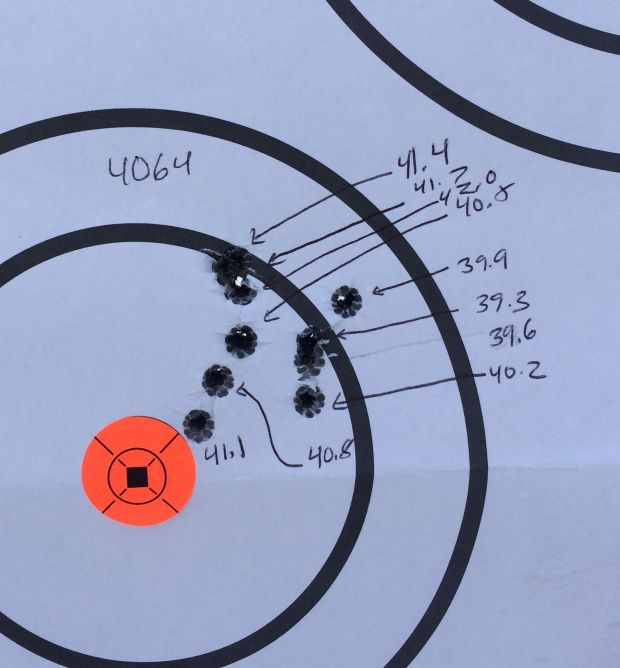

Things improved with the IMR 4064 ladder, I only had to hike through the snow twice. The IMR 4064 ladder was more impressive. Note the first cluster at 39.3, 39.6, 39.9 and 40.2 grains, and the second at 41.4, 41.7, and 42.0 grains. The last three rounds, impacted into one ragged hole .179″ (.085 MOA)! I’ll be working up some loads for further accuracy testing at this distance.

I found ladder testing uses less bullets and powder than the traditional method (especially if you are only shooting 10 rounds). The downside is you need to record the impact of each round. I had an excellent spotting scope and still needed to walk downrange with the lighting conditions. If you have access to a facility with a butt system for targets, you could head to the range with your friend and conduct a ladder test at greater dustances. If you don’t have access to one, you’ll be limited by the distance you can see the bullet holes on your target with a spotting scope. For most, especially with smaller diameter projectiles, this distance will probably be 200 or 300 yards.

Like this? Subscribe to Rifleshooter.com (top right corner) and never miss a post!

You must be logged in to post a comment.